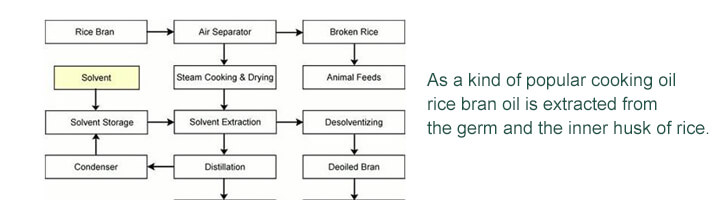

As a kind of popular cooking oil, rice bran oil is extracted from the germ and the inner husk of rice. It is noble for its high smoke point and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. What’s more, eating rice bran oil helps lower cholesterol, fight diseases, enhance the immune system, and fight free radicals and more. Rice bran oil manufacturing processes mainly includes rice bran oil expelling, extraction and

Rice bran oil mixture was evaporated

PRODUCT DETAILS Rice bran oil mixture was evaporated: the use of non-volatile oil is almost, but low boiling point solvents, easy volatilization characteristics, the use of steam heating coils vaporize most of the solvent was distilled off, so that the fat concentration in the mixed oil is greatly improved. Hybrid rice bran oil to start mixing tank into the first long tube evaporator tube, solvent evaporation into the separation chamber via a steam condenser; mixing oil concentrated into the second

The extraction process of rice bran oil

PRODUCT DETAILS The extraction process of rice bran oil, rice bran is a byproduct of processing, rice bran oil from rice bran layer is larger Mi Maipi preparation oil, rice bran oil content of 15% to 22%. Rice bran oil is a high quality edible oil, the advantages of promoting the growth of human health, essential fatty acids, resistant to preservation, anti-oxidation, which contain, also known as the “healthy oil”, “nutrition oil.” Rice bran oil extraction process and refining process

Rice bran oil extraction process

PRODUCT DETAILS Rice bran oil extraction process: rice bran oil plant process design, including pretreatment, extraction and refining process. The former has rice bran cleaning process, puffing process, the drying process; latter has meal, oil two process routes: a puffed bran, leaching, steaming off, finished meal, two extruded bran, leaching, evaporation mixed oil, gas mention, refined crude oil. Rice bran oil extraction process indicators: Leaching temperature: 50 ℃ Extractor operating cycle: 80 ~ 100 minutes Solvent ratio: 1: 1 to

Oil extraction equipment

PRODUCT DETAILS Oil extraction equipment: leaching equipment types vary widely, the general design process design should be. However, now more mature leaching processes. Its equipment includes: extractor, desolventizing grilled meal, a mixture of oil evaporator, stripper, exhaust absorber, water separator and a variety of heat exchangers, vessels and pumps and so on. Most of equipment belonging to the ordinary chemical equipment, chemical equipment design specifications can be mechanical and structural design. To this end . The following describes only the

Classification leaching process equipment

PRODUCT DETAILS Classification leaching process equipment, single-stage leaching equipment: single-stage leaching process equipment is a leaching tank, it is the herbs and the solvent was added to the extractor, extract a certain time after the collection of leachate and discharge dregs of equipment, such as multifunctional extraction tank. Single stage leach leaching speed change is large, the initial speed is high leaching, the leaching rate reaches zero equilibrium leaching. Multi-stage leaching equipment: multi-stage leaching process equipment consisting of a plurality

Oil leaching process

PRODUCT DETAILS Fat oil leaching process can press oil into the leaching pretreatment methods and divided into a leaching method, to squeeze leaching method, extrusion method, wet and heat treatment (Alcon) leaching method, etc.Adopted by leacher type can also be in accordance with the characteristics and divided into tank group type leaching, swing type, ring type leaching apparatus and so on.But neither the immersion oil or leaching shape difference, the difference between a their leaching process is basically the same.These

Leaching oil extraction technology

PRODUCT DETAILS Leaching oil extraction technology, the equipment is a kind of professional equipment to extract oil, it will push the grease of the clutter and useless content filtering out, so we need crude oil. Waste clay leaching oil extraction technology is a kind of edible oils and fats industry decolorization of waste clay leaching after oil extraction process, its characteristic is that includes the following steps: 1, material: be on the waiting list waste clay, ceramic clay, gypsum powder,

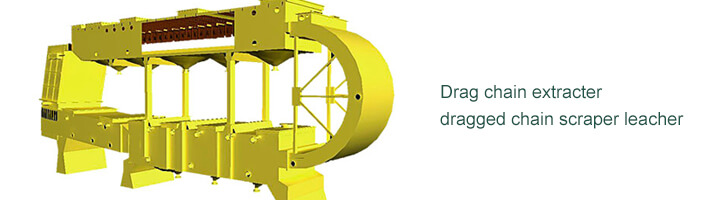

Drag chain extracter

PRODUCT DETAILS Drag chain leacher, also called dragged chain scraper leacher. In the view of structural form, it’s similar to crawler leacher. It can also be regarded as a circular leacher derivatives, equivalent to cancel the bending section, to the lower level of separation of ring structure merged into a box structure. Its leaching principle with annular leacher similar, although cancelled the bending section,but the material from the upper left, lower in turn institution can make the material under the

negative evaporater

PRODUCT DETAILS The mixture was filtered after the pump into the first evaporator, a portion of the solvent was distilled off, the concentration of the mixed oil from 18% to 30% -20% -35%. And then into the second evaporator, the oil concentration of the mixture was further increased to 95%, and finally fed to the stripper is stripped of residual solvent to obtain a crude rice bran oil. Vacuum evaporation advantages: 1, the evaporation temperature is low, the secondary steam