PRODUCT DETAILS Oil extraction equipment: leaching equipment types vary widely, the general design process design should be. However, now more mature leaching processes. Its equipment includes: extractor, desolventizing grilled meal, a mixture of oil evaporator, stripper, exhaust absorber, water separator and a variety of heat exchangers, vessels and pumps and so on. Most of equipment belonging to the ordinary chemical equipment, chemical equipment design specifications can be mechanical and structural design. To this end . The following describes only the

Classification leaching process equipment

PRODUCT DETAILS Classification leaching process equipment, single-stage leaching equipment: single-stage leaching process equipment is a leaching tank, it is the herbs and the solvent was added to the extractor, extract a certain time after the collection of leachate and discharge dregs of equipment, such as multifunctional extraction tank. Single stage leach leaching speed change is large, the initial speed is high leaching, the leaching rate reaches zero equilibrium leaching. Multi-stage leaching equipment: multi-stage leaching process equipment consisting of a plurality

Oil leaching process

PRODUCT DETAILS Fat oil leaching process can press oil into the leaching pretreatment methods and divided into a leaching method, to squeeze leaching method, extrusion method, wet and heat treatment (Alcon) leaching method, etc.Adopted by leacher type can also be in accordance with the characteristics and divided into tank group type leaching, swing type, ring type leaching apparatus and so on.But neither the immersion oil or leaching shape difference, the difference between a their leaching process is basically the same.These

Leaching oil extraction technology

PRODUCT DETAILS Leaching oil extraction technology, the equipment is a kind of professional equipment to extract oil, it will push the grease of the clutter and useless content filtering out, so we need crude oil. Waste clay leaching oil extraction technology is a kind of edible oils and fats industry decolorization of waste clay leaching after oil extraction process, its characteristic is that includes the following steps: 1, material: be on the waiting list waste clay, ceramic clay, gypsum powder,

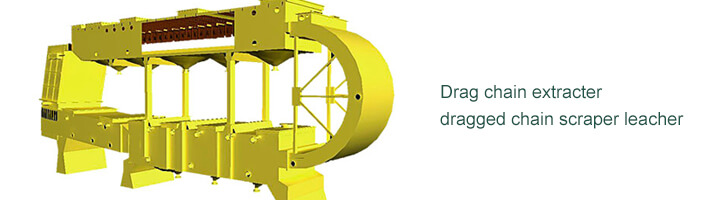

Drag chain extracter

PRODUCT DETAILS Drag chain leacher, also called dragged chain scraper leacher. In the view of structural form, it’s similar to crawler leacher. It can also be regarded as a circular leacher derivatives, equivalent to cancel the bending section, to the lower level of separation of ring structure merged into a box structure. Its leaching principle with annular leacher similar, although cancelled the bending section,but the material from the upper left, lower in turn institution can make the material under the

negative evaporater

PRODUCT DETAILS The mixture was filtered after the pump into the first evaporator, a portion of the solvent was distilled off, the concentration of the mixed oil from 18% to 30% -20% -35%. And then into the second evaporator, the oil concentration of the mixture was further increased to 95%, and finally fed to the stripper is stripped of residual solvent to obtain a crude rice bran oil. Vacuum evaporation advantages: 1, the evaporation temperature is low, the secondary steam

Rotocel extractor

PRODUCT DETAILS The rotocel extractor works: the transmission to drive the rotor and the rotor material within the rotation by a fixed sprinkler system mixed oil spray, soak, drain, rinse with fresh solvent in order to achieve the extraction of material oil. After taking the oil feed meal after a feeding device unloaded out. Rice bran extraction process uses a combination of spray soaking the pan and filter extractor. It is connected together along a peripheral direction of the tank

Steamed rice bran oil off the leaching process

PRODUCT DETAILS Steamed rice bran oil off the leaching process, rice bran metering cleaning and drying to leaching plant puffing, puffing bran rice bran oil extraction evaporation finished meal mixed solvent containing dissolved meal solvent recovery, extraction of crude oil condensate stripping off by puffing steam into the leaching plant after first to enter the extractor seal auger to seal the leak spilled solvent, bran into the extractor after puffing, split in different material lattice to be the way countercurrent

Steaming rice bran Fried purpose

PRODUCT DETAILS Steaming rice bran Fried purpose: to make through steaming Fried rice bran of grain increase, is advantageous to the solvent penetration and reduce the solvent content in the bran meal, it to the operation of the whole leaching process have a significant impact. When steaming and frying, should be add water and directly into the steam, adjust the moisture of material pulp, evaporate and the temperature of the material after embryo should be 108-110 ℃, water content of

Heat conduction oil frying pan

PRODUCT DETAILS Heat conduction oil frying pan steaming and frying can make oilseed cell structure destroy completely , dispersion of free oil gathering; Clotting protein denaturation, combined with state oil exposure; Heat conduction oil frying pan phospholipids swell; Reduce oil viscosity, surface tension. As a result, the heat conduction oil frying pan evaporate and promote the condensation of grease, is advantageous to the oil flow, to improve the yield efficiency provides a guarantee. Heat conduction oil frying pan steaming and