Rice grader is a normal equipment in rice mill plant. Is it necessary to do rice grader? How does the rice grader work? So let’s have a detailed understanding of rice mill grader today with HDC.

Rice Thickness Grader

It is a kind of cleaning equipment for separating grain particles. The octagonal sieve cylinder rotates around the horizontal axis to classify grain particles and plant seeds with different thickness, so as to achieve the purpose of removing impurities or rice grading.

The specific method is as follows: by setting a relatively independent sieve cylinder, each sieve cylinder is inclined to the discharge end, and the grains entering each rotating sieve cylinder flow out of the sieve cylinder while screened at the same time. The full and complete brown rice grains are larger than the size of the sieve hole roll to the outlet end of the sieve cylinder with the help of the inclination with the sieve cylinder, The immature particles will pass through the sieve drum.

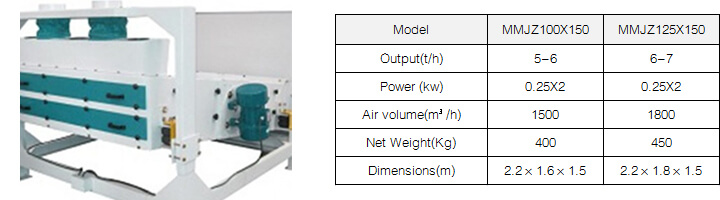

Rice Length Grader

White rice classification screen is to make use of the difference between broken rice and whole rice grain shape, make overlapping rotation on the plane rotary screen surface, and form automatic classification by friction propulsion. The three-layer and four layer equipment adopts the technology of extracting whole rice for two to three times, so the classification performance is better.

Rice Grading Machine Price

The price of rice grading machine will be quite different according to their specifications. Mostly, the price varies from 1000 – 10000 dollars.

Is it necessary to use a rice mill grader in your rice mill plant?

For the business owners who aim to low-end market, there is no demand to grade the rice, you can sell it directly. However, if you want to add more value to the rice and make a higher price for your rice product, the grading process will be necessary, and you may even take rice color sorting machine into consideration.

Share your thoughts Cancel reply

Your email address will not be published.

Comment *